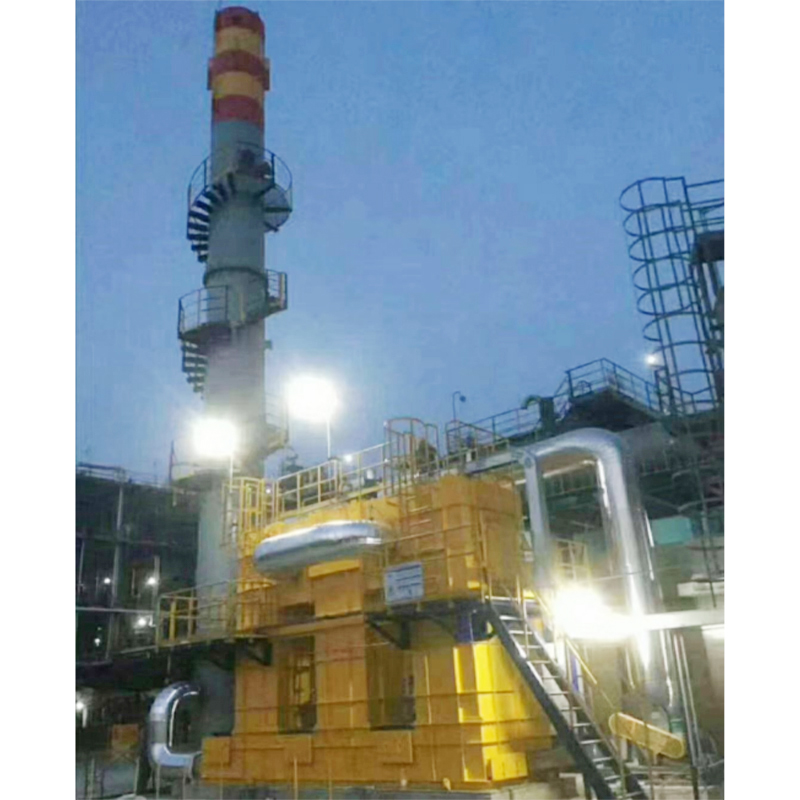

RTO Supporting Waste Heat Boiler

**RTO (Regenerative Thermal Incinerator) supporting waste heat boiler** is a device that recovers the heat of waste gas generated during the incineration process of RTO and converts it into useful energy such as steam, hot water or power generation using waste heat boiler. RTO equipment is widely used in waste gas treatment, especially in some organic waste gas treatment fields, such as chemical, pharmaceutical, coating, plastic, printing and other industries. Through the supporting application of waste heat boiler, RTO can not only efficiently treat waste gas, but also recover and utilize the heat energy in waste gas, improve energy utilization efficiency, and reduce environmental pollution.

1. **Application scenarios**

The application scenarios of RTO supporting waste heat boiler mainly include:

- **Chemical industry**: Organic waste gas generated in the chemical production process usually needs to be incinerated by RTO. The supporting waste heat boiler can recover the heat energy in the waste gas and provide steam or hot water for the production process.

- **Pharmaceutical industry**: In pharmaceutical production, RTO is used to treat organic waste gas, and the heat in the waste gas is converted into useful energy through the supporting waste heat boiler to reduce energy costs.

- **Coating industry**: A large amount of organic waste gas is also generated during the production of coatings. RTO can effectively treat these waste gases and recover the heat energy in the waste gas through waste heat boilers to reduce energy consumption.

- **Plastic industry**: Organic waste gas is emitted during the production of plastics. RTO-equipped waste heat boilers can convert the heat of waste gas into steam or hot water to provide the necessary energy for the production process.

- **Printing industry**: The waste gas generated during the printing process can be incinerated through the RTO system, and the supporting waste heat boiler can recover the heat energy in the waste gas for other energy needs in the factory.

- **Other organic waste gas treatment industries**: Organic waste gas generated by industries such as food processing and petroleum processing can also be treated and heat recovered through RTO and waste heat boiler systems.

2. **Purpose**

The main uses of RTO-equipped waste heat boilers include:

- **Power generation**: By recovering the waste gas heat generated during the incineration of RTO, the waste heat boiler can convert it into steam to drive the steam turbine to generate electricity for the production process or factory area, reducing the demand for external electricity.

- **Heating**: Waste heat boilers can convert waste gas heat into hot water or steam for heating needs within the factory, or provide hot water, steam and other energy to surrounding facilities and areas.

- **Energy saving and emission reduction**: By recovering the heat in RTO waste gas, waste heat boilers can significantly reduce the demand for external energy, reduce energy consumption, and help reduce the burden on the environment, in line with the policy requirements of energy conservation and emission reduction.

- **Waste gas cooling and environmental protection**: Waste heat boilers can reduce the temperature of waste gas and reduce the thermal pollution of waste gas to the environment. At the same time, by efficiently treating waste gas, they help reduce the emission of harmful substances in waste gas and ensure compliance with environmental emission standards.

3. **Features**

- **Efficient heat recovery**: The waste gas temperature during RTO incineration is usually high, and waste heat boilers can efficiently recover the heat therein and convert it into useful energy, such as steam, hot water or electricity.

- **High temperature and corrosion resistance**: RTO waste gas contains corrosive gases and high-temperature waste gas, so waste heat boilers need to have good high temperature and corrosion resistance to ensure its long-term stable operation.

- **Modular design**: Modern waste heat boilers usually adopt modular design, which can be flexibly configured according to the specific needs of the production plant, and is easy to install and maintain later.

- **Intelligent control system**: The waste heat boiler is equipped with an intelligent automatic control system, which can adjust the boiler operation in real time according to the temperature, flow rate and other parameters of the exhaust gas to ensure its efficient and stable operation.

- **Strong environmental protection performance**: The waste heat boiler can effectively reduce the exhaust gas temperature, reduce the emission of harmful substances in the exhaust gas, and help enterprises meet environmental emission standards.

- **High energy efficiency**: Through the efficient heat recovery of the waste heat boiler, the heat in the exhaust gas can be converted into useful energy, greatly improving the energy utilization efficiency and reducing the energy consumption in the production process.

4. **Advantages**

- **Energy saving and consumption reduction**: The RTO supporting waste heat boiler can recover the heat in the exhaust gas, reduce the consumption of external energy, reduce production costs, and thus improve the overall economic benefits.

- **Increase energy self-sufficiency rate**: By recovering and utilizing the heat in the RTO exhaust gas, the waste heat boiler can provide part of the energy for the factory, reduce dependence on external electricity and fuel, and improve energy self-sufficiency.

- **Reduce environmental pollution**: By efficiently recovering the heat of waste gas and converting it into useful energy, waste heat boilers can reduce the temperature of waste gas, reduce thermal pollution to the environment, and help enterprises reduce the emission of harmful substances in waste gas, meeting environmental protection standards.

- **Promote green and low-carbon development**: By recovering the heat energy in waste gas, waste heat boilers reduce the demand for traditional fossil energy, reduce greenhouse gas emissions, and promote the green and low-carbon transformation of enterprises.

- **Reduce energy costs**: Waste heat boilers can convert waste gas heat energy into steam, electricity and other energy, reduce the demand for external electricity and energy procurement, and significantly reduce energy costs.

- **Improve production efficiency**: By improving the utilization efficiency of waste gas heat energy, enterprises can improve the overall efficiency of the production process without increasing additional energy consumption.

- **Comply with regulatory requirements**: RTO-equipped waste heat boilers can not only improve energy utilization, but also help enterprises meet environmental emission requirements and meet increasingly stringent environmental regulations.

Summary

RTO-equipped waste heat boilers, as an advanced waste gas heat recovery technology, are widely used in waste gas treatment systems in chemical, pharmaceutical, coating, plastic, printing and other industries. By efficiently recovering the heat in RTO waste gas, waste heat boilers can provide electricity, hot water, steam and other energy for the production process, while significantly reducing energy consumption, reducing environmental pollution, helping enterprises reduce production costs, improving energy self-sufficiency, and promoting green and low-carbon development. In the context of increasingly stringent environmental protection policies and rising energy costs, RTO-supported waste heat boilers will become a key technology for enterprises to improve their competitiveness and sustainable development.