High temperatures also accelerate the formation of nitrogen oxides, requiring emissions control through combustion adjustment or exhaust gas treatment technologies.

- +86-18951574005

- hhx@wxboilerchina.com

- No. 99-1, Shengli Road, Yangshan Town, Huishan District, Wuxi City, Jiangsu Province

- Home

-

Our Services

- Gas Boiler

- Waste Heat Boiler

- Direct Fired Waste Liquids and Gases Boiler

- Biomass Boiler

- Bubbling Bed Boiler

- Petroleum And Natural Gas Chemical Industry Skid

- Various Heat Exchangers

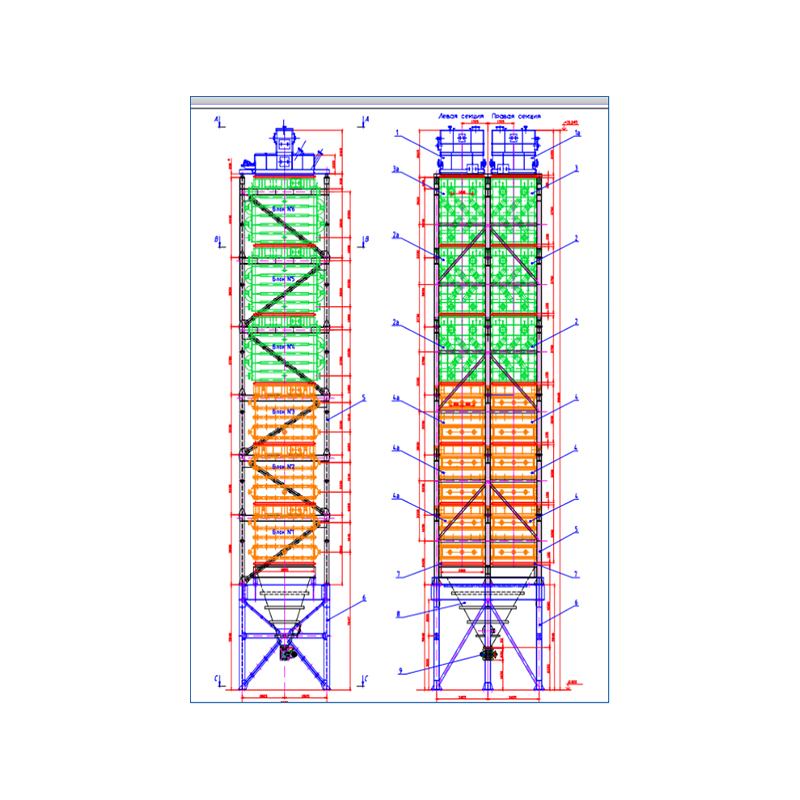

- Circulating Fluidized Bed Boiler

- Ash Heat Exchanger

- Denitrification And Dust Removal Project

- Desulfurization And Dust Removal Project

- Display

- Solutions

- News

- About

- Partners